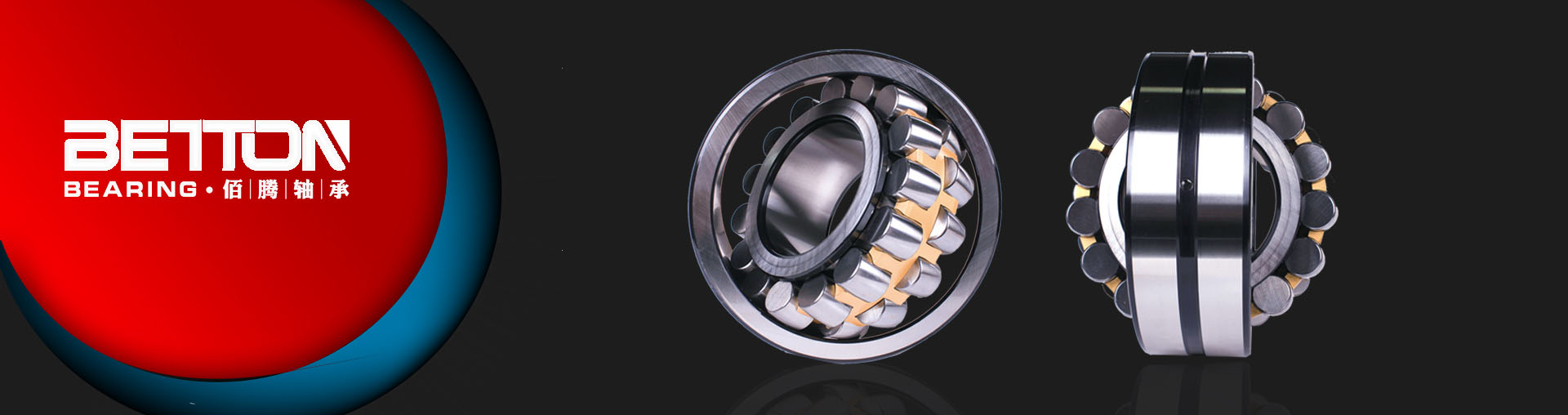

Self-aligning ball bearing has two structures of bore

cylindrical and capered, the material that made into the rearing are steel

sheet, synthetic resin and so on. The feature is spherical outer ring raceway

and automatic aligning, which can make up the error. But it shall not exceed 3

degree of the relative gradient. Its lowest friction among the rolling bearings

leads a smaller temperature rise even at high speed.

Self-aligning ball bearings mainly endure radial load and

also take small axial load. With self-aligning function when axle (casing)

limit the axial displacement within the clearance limit. They can work properly

under the incline of internal and external conditions are not significant.

These bearings are applying to the parts which of the bearing block hole cannot

guarantee the same coaxial tolerance.

Self-aligning ball bearings with cylindrical bore and

tapered holes. The materials of cages are steel, synthetic resins, etc. Which

is characterized by the outer ring raceway is a spherical shape, with

auto-mind, can compensate the different heart and shaft deflections caused by

error, but, the outer ring relative gradient of not more than 3 degrees.

Shielded and self-aligning ball bearing assembly with

sealing ring filled appropriate amount of grease at the time. It should not be

heated or cleaned before installation. The bearings do not need lubrication

during use, they adapt to operating temperatures between-30 ° c to + 120 ° c.

Application: Precision instrument, Low noise motor, Automobile,

motorcycle and other machines.